Main Features

- Outside case made by high-quality Sheet steel

- High resistance to corrosion

-Diaphragm made for an endurance life cycle as per EN1359

- Starting flow-rate: ≤ 1.0dm3/h

- High accuracy and long reliability

- Low noise level

- Fire resistant (HTB) up to 0.1 bar according to EN1359

It is a compact residential gas meter designed to accurately measure volumes of natural gas, LPG and all noncorrosive gases. Its design minimizes installation costs and enables future field upgrades.

Application

The meter meets MID and EN1359 (certificate delivered by CMI). Its compact design makes the right choice where a precise and reliable measurement for medium flow rates is required.

Metrology

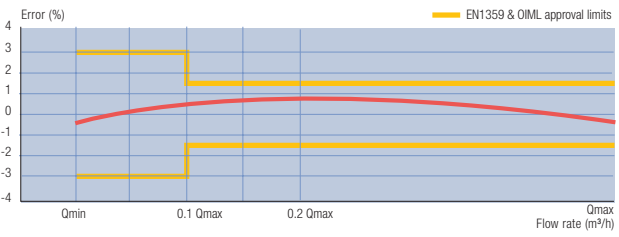

During preliminary test bench controls, the meter is 100% tested according to customer or national requirements.The design and the careful materials selection enable it to meet the highest demand in international markets in terms of accuracy and long-term stability.During the preliminary test controls on the sonic nozzle test benches, all meters are tested at Qmin, 0.2 Qmax and Qmax.

Operating Principle

The meter is a positive displacement diaphragm gas meter with a stand-alone twin chamber measuring unit. The twin chambers are each fitted with a flexible and gas-tight diaphragm, which is moved by the differential between the inlet and outlet pressure. Gas enters one side of the diaphragm plate, while on the other side it sluice through a separate port on the valve. When one side is full, the rotating mono-valve moves on to the next position, allowing the gas to fill the empty side. A transmission gear and a mechanical coupling or stuffing box transfer the reciprocating motion to the mechanical index.The measuring unit is housed in a robust, gas-tight casing.

Accuracy curve

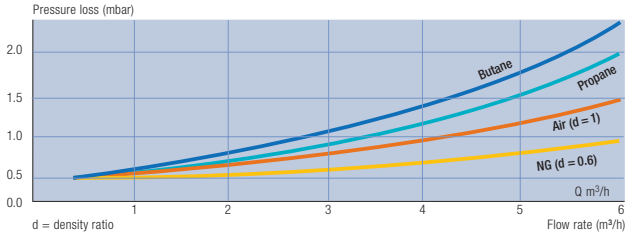

Pressure loss curve

Technical parameters

Item | Unit | G1.6S | G2.5S | G4S | |

Nominal flow-rate | m3/h | 1.6 | 2.5 | 4 | |

Max flow-rate(Qmax) | m3/h | 2.5 | 4 | 6 | |

Min flow-rate(Qmin) | m3/h | 0.016 | 0.025 | 0.04 | |

Accuracy | Class 1.5 | ||||

Mechanical Environment | M1 | ||||

Electronical Environment | E2 | ||||

Approvals | MID, EN1359 & OIML R137 | ||||

Casing material | Steel | ||||

Centre distance | mm | 110 or 130 | |||

Total pressure loss | Pa | ≤200 | |||

Max working pressure | bar | 0.5 | |||

Cyclic volume | dm3 | 1.2 | |||

Error | Qmin≤Q<0.1Qmax | % | ±3 | ||

0.1Qmax≤Q≤Qmax | % | ±1.5 | |||

Display range min. | dm3 | 0.2 | |||

Display range max. | m3 | 99999.999 | |||

Operation ambient temperature | ℃ | -25(-40) to +55 | |||

Storage temperature | ℃ | -40 to +60 | |||

Pulse magnet built-in | m3/pulse | 0.01 | |||

Totalizer | IP65 | ||||

Connection threads | ISO228-1 standards: G3/4”; G1”; G1?" | ||||

NPT/BSP/S746 standards: 3/4” | |||||

Metric standards: M26x1.5; M30x2 | |||||

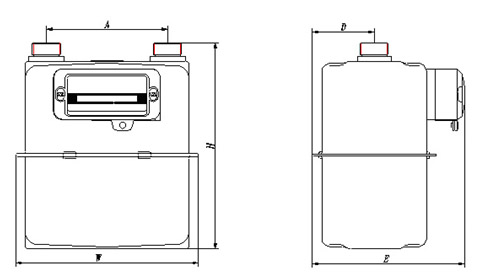

Sizes

| Model | H | W | D | E | A | Weight |

G1.6S, G2.5S & G4S | 224mm | 195mm | 67mm | 165mm | 110(130)mm | 1.90Kgs |